Every day, I get calls from customers who want to know everything about how to use our machines. Sometimes they’re simple to answer, but some other more complex questions have no quick answers. So I thought it would be a good idea to answer those questions via this blog. In this entry, I’ll answer the question:

What is a poker vibrator?

The simplest answer is: a poker vibrator is a machine to (internally) compact concrete. However, this answer doesn’t do justice to the complexity and diversity of a poker vibrator. There are so many different types and versions available based on different technologies and for different fields of applications, and at first sight it’s often not clear what the difference is. At Lievers, we differentiate between the following types:

- Mechanical pendulum poker vibrator

- Mechanical rotating poker vibrator

- High frequency – 42V poker vibrator

- High frequency – 230V poker vibrator

- Pneumatic poker vibrator

- Hydraulic poker vibrator

Each of these types performs the same function: compacting concrete. But they all have different ways of doing it. In future blog posts, I’ll explain the specific characteristics of each type of poker vibrator. In this BLOG I will first cover the basics.

Main components of a poker vibrator

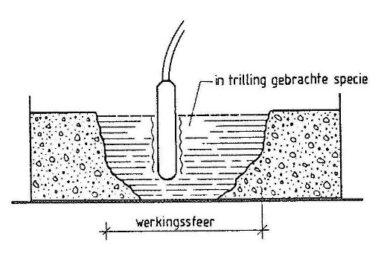

Every type of poker vibrator has a component that inserts into the concrete mix. This a a metal cylinder is referred to as the vibrating bottle, and contains the mechanism that generates the vibrations.

The vibrating bottle is often connected to the other components of the poker vibrator via a rubber hose,.

Poker vibrators used for compacting floors are often equipped with a short shaft to keep the machine lightweight and make it easier to carry and insert into the concrete. This type is also referred to as a ‘hand-held poker vibrator’, because you can hold it while compacting the concrete.

If you want to pour a wall, column or pillar, then you probably want to use a poker vibrator with a longer shaft. With the longer shaft you can move the poker vibrator all the way into the formwork, so that it can compact the mix that is placed deep inside the form.

In a mechanical poker vibrator, the shaft connects the tip to a drive mechanism. Inside the shaft is a mechanical drive spring that powers the vibrator mechanism in the tip. Depending on the type of drive, the machine may also have a power cord.

In a high-frequency poker vibrator, a rubber hose connects the vibrating bottle to a switch box. This is because in a high-frequency poker vibrator, the drive mechanism is integrated into the bottle. Through the hose only electrical wires run that power the electronic vibrating mechanism . The on/off switch to operate the poker vibrator is located in the control unit.

So far about the basic elements of poker vibratos. In upcoming blog posts, I’ll go into more detail about the differences between the different types of poker vibrators, the pros and cons of each type, both technically as in practical use, and I will discuss for which fields applications the respective types are best suited.